Mar 14, 2022

TIMBER [ˈtɪmbə(r)]: trees that are grown to be used in building or for making things

PLAUSCH [plaʊ̯ʃ]: german expression for ‘social gathering’ or ‘cheerful chat’

Timber Plausch is an interview series to unravel the essence of the IntCDC projects, meet the researchers behind these projects and understand their work routines and passion for wood.

For our first interview as part of the Timber Plausch series, we got the chance to chat with with Laura Kiesewetter and Dylan Wood. They are part of the Cluster of Excellence – Integrative Design and Construction for Architecture (IntCDC) at the University of Stuttgart. Their work revolves around self-shaping wood. They founded together Hylo Tech: As a design team they develop self-shaping furniture, high performance building components and adaptive systems. As part of the Timber Plausch series, we had the chance to ask them about the research project, their work processes and their passion for wood.

digitize wood Dylan and Laura, how would you explain your work to a kid or your grandparents?

Laura I have explained it to my grandma and last year we had the “Girl's Day” which is for school girls aged eight to 16, where we had a half a day event talking about material programming.

Most people have heard of the bimetal where one side expands more than the other side when the surrounding conditions change, such as heat. It's the same with wood, just in this case, the boundary conditions are relative humidity in the air. If someone has heard about bimetals, I think he/she can very easily understand our research.

digitize wood The only difference would be the fact that instead of heat humidity is the affecting factor, right?

Laura Yeah. Exactly. And I mean, of course, bimetals are much simpler than wood. It's a bit more complex because it has fiber orientations, whereas metal is a completely isotropic material that would perform similarly in all directions.

Dylan For my side, I grew up in a wood house and I guess most people know that if your door frame is made of wood, then, in different times of the year like in summer or winter, sometimes the door doesn't close because the whole doorframe can move around a little bit.

Or the other example, like if you have a wooden spoon for cooking or a cutting board, and you would leave this sitting in the water or put it in your dishwasher, then oftentimes it will come out all crooked or going in one direction. And this is the same principle that we use to our advantage. I guess everyone that has ever had a wooden spoon would probably understand.

digitize wood Yes exactly!

For years now, you have been researching self-shaping wood. We would like to know what fascinates you about this topic to get you jumping out of bed and excited to go to work each day.

Laura I guess for me, what was most exciting about the process was when we were working on these things digitally and making the first prototypes, then developing the chair and then watching it self-shape with a time-lapse. Watching the recording for the first time was really exciting. And it's still exciting for every prototype.

Dylan I mean, for me it's, I also actually worked with wood before. And so, I sort of came from this smart materials-based research. And what is fascinating about wood is that it's not necessarily engineered to do that, but it works at a scale and with a force where it can change shape which is, as far as I know, not possible with any other more engineered material. So, it really has this super unique behavior right now.

I don't know, maybe in 20 years, we have some engineered material that's specifically made to change shape. But with wood, somehow it has this sort of natural capacity to be stiff enough to change shape at a larger scale, like on the scale of a meter or two meters.

We do a lot of biologically inspired work, but what’s fascinating to me here is that it goes one step further because it's really taking the biologically innate behaviour or property or structure of the material even, and then trying to figure out how to use computational design to instrumentalize that natural material even more.

So to me, the epitome of what we want to do is somehow to figure out how to use it even more. I think it needs to be studied with more intensity. We work with expert biologists in Freiburg, and when we meet with them, we realize every time that we are really on the tip of the iceberg in terms of understanding how materials in nature work.

So not just wood, but even in plants in general and I think there's a huge potential for looking at these types of things. Oh, you would think that for five, six years I studied self-shaping wood but some biologists have been studying pine cones for 20 years.

And there are still so many things that they don't know or every time they figure out something new about the pine cone you realize that there's a lot more to be done there so to me the most exciting part is that there's so much that could still be done.

digitize wood Thank you! I think now we know a bit more about your research. We would love to know more about your day-to-day work as well. We assume there might not be a typical day in your role. So, we’re wondering whether you could share what your day looked like today?

Dylan Oh, today! (laughs) This is going to be good.

Laura This was not a very typical day! We just had another interview with the local radio station SWR2 and we're going to be on the radio soon! I guess that was a big part of the day. And then in parallel, we're both working on other things at our institute, the ICD. So it was a bit of replying to emails, and checking with wood companies for our teaching. So half of the day was the usual stuff but the other half was very exciting.

Dylan My day started very early. I had to go to Waiblingen [to the workshop] because I had to help my colleague fix a prototype that is constructed there. So I rode my bike to Waiblingen, and then we were outside working for like two hours. And then I came back, I worked on a paper. And then we had this interview and worked a bit on some visualizations for the FIT Project [the next building demonstrator] and talked to Laura about a clip, like a clip for holding a climber so that we can access the window in the building. That meeting was the best meeting ever talking to all the professional climbers who climb up to fix the windows last week. And then, yeah, then we had the interview. And on Mondays, we always have this jour fixe meetings for another building project that actually we're also both working on. So yeah, actually it was a full day. But it's usually a mix of working full time in Waiblingen because we have a lab there. So usually once I go there to visit them or we visit companies that we're working with, it's a lot of like back and forth.

digitize wood So what fascinated us also to choose you as our first interview is this knowledge transfer that's happening, from research done to the actual building with the Urbach Tower and then moving on to the furniture. So moving through this big world, going to the small world. And we were wondering, how this process happened and how come you, as architects, moved from architecture to this very small scale of furniture.

Dylan Yeah. So that's also actually a really good question because usually chairs are something that architects teach or use as a demonstrator in a project.

And here it's almost in reverse. So, we had the idea to make furniture after I finished my masters in ITECH [Integrative Technologies and Architectural Design research, study program at the University of Stuttgart]. But instead, we partnered up with some wood scientists at ETH Zurich, and they were very keen on using it for sort of larger-scale applications. So we decided to work with them.

With working with them, we also got connected to timber construction companies, and they were not interested in furniture at all. So they wanted to go big and I guess we rode that train or took that path as it was available at the time. We went through the process with the tower and then now we have come back to working out the furniture idea.

And I think what is very interesting is that now, the furniture has revealed some very interesting things about being able to do the shaping onsite and with higher curvatures than what we sort of investigated in the Urbach Tower. So, what’s quite interesting is that we see it going full circle back. So we sort of did the big scale, then moved to the smaller scale and took what we learned, to go back to the bigger scale or architectural buildings. And we are working on this bigger scale both in studio and personal projects.

Laura Yeah. And just to clarify, the studio that Dylan is talking about is the current ITECH studio that Dylan and I are teaching. The furniture also in this case, we kind of see as a way to demonstrate the principle and showcase in one piece what self-shaping can do so people believe that it's possible. Additionally, I believe that it can be a really cool product.

Dylan It's also true that the chair makes it understandable to people. If I tell people that I'm going to self- shape a house or a wall they won’t really get it.

They will if you explain it... but there's something so direct and understandable to the general public about the furniture that is really nice. It's almost like a better way of explaining our work.

digitize wood Can you tell us about this next architectural application?

Dylan It's a good question. Yeah. Maybe the studio we're not supposed to say, but I think the more general applications to work for sure.

Laura Yeah, there's nothing really concrete now. We're just continuing to work on it. So, my Ph.D. will probably also be on this topic of self-shaping building components, which we could imagine for walls and ceilings and rooms or spatial trusses, a bunch of applications.

And I think if we have an interview again in one year, I could probably tell you much more about it.

digitize wood Yeah. I just wanted to explain why we also wanted to ask this question. Seeing you move from this big scale to the small scale, the question arose: do you actually see more potential in this small scale of furniture?

Dylan I mean, there's a lot of potential in both. But we are both architects and IntCDC is full of architects. Therefore, our larger objective is to build components, systems, or even structures. But at the same time, we've seen that both locally and internationally there's quite a lot of momentum and interest in the furniture. Hopefully, eventually, we will find people who would be able to capitalize on our ideas.

digitize wood I think we're moving to the last question. If you could switch research projects at the institute with any other person at the cluster, which one would it be and why?

Dylan [laughs] I don't know. I mean, I just want to be a biologist. That's it.

I mean, I think you just have to go to one of these inter-disciplinary meetings. Biologists, unlike engineers who strive for conclusive answers, never have firm answers.

I think that when they look at something like the pinecone, they never really know. It seems that they just gather enough evidence to make an educated guess. So in some ways, maybe this would be frustrating because you can only get so far right, and most of the time some findings raise even more questions. Whereas engineers strive towards getting fewer questions and one concrete answer. Or maybe I have the wrong impression of biologists, I don't know. One thing for sure is that we need more biologists and more connections to them.

But in IntCDC…? Yeah, I will go around your question [laughs].

digitize wood That’s accepted [laughs].

Dylan What's your answer, Laura?

Laura Maybe I wouldn't stray very far and I would just choose to be an engineer at ITKE [Institute for Building Structures and Structural Design at the University of Stuttgart]. I would just really like to use all the tools that the structural engineers at ITKE have and then apply them to the self-shaping project. I would maybe like to do like a workshop for one week there and then come back to the self-shaping.

Dylan So, you want more concrete answers then.

Laura Yes.

Dylan That's a good question. That's way more interesting.

Maybe I would switch with Jakob [Hans-Jakob Wagner, Doctoral Researcher at IntCDC], but if I could start over completely, I would want to work with Katherine J. Kuchenbecker’s group that does haptic intelligence. Because this also is just really fascinating somehow to be at the interface between machine and the human. It is completely a different field, although we do get a lot of weird inquiries for publishing in similar human interaction fields.

Problem statements such as how people can feel, how machines can feel, or even how people can feel machines are all interesting questions. So yes, I want to be part of this group.

Laura I wonder if Kathrin would also want to be you?

Dylan Should I ask her? I think she really thrives on this sort of human aspect. Maybe the chair that moves with the person.

digitize wood We have one-minute last question. Do you have a paper and a pen in front of you?

We would like you to sketch your connection to wood in one minute, or rather your love your interests... How do you see yourself concerning wood?

Dylan That's so easy for me. [Shows a paper written Dylan WOOD on it.]

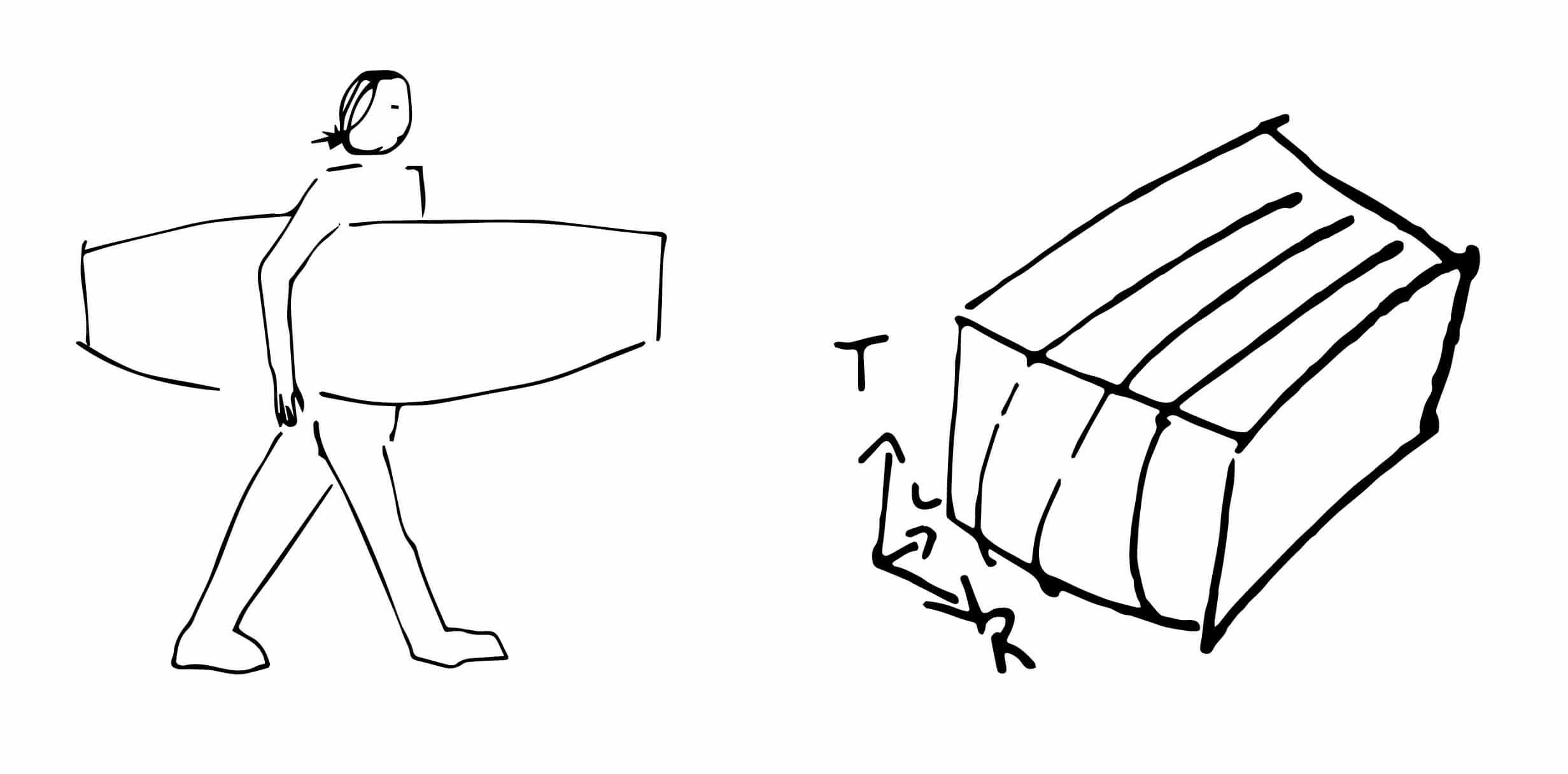

Laura [Shows a sketch of her holding a wood piece looking like a surfboard.]

digitize wood Oh, Laura and her surfboard?

Laura Oh, yeah. I would go walking through university with the chair under my arm and I can't count how many times people asked me if it's a surfboard.

Dylan This is the sketch that I would make because I think this is the key to the whole idea.

[Shows a sketch of a cubic piece of wood with three axis.]

If you were to three-axis we digitize wood I would say, that’s the total key: understand that it has a coordinate system. Because of that relatively defined coordinate system, we can also somehow program with it, right? Just like you learn how to program a KUKA robot, one should have the same approach when dealing with wood: taking into account the fact that it has this three-axis coordinate system. Three-axis is not very personal, so maybe you can take my name as a sketch.

digitize wood Thank you. It was really fun, at least for me, and very insightful. Thank you so much for your time, answers, and creativity.

Laura Kiesewetter is a research associate at the Institute for Computational Design and Construction (ICD) at the University of Stuttgart. She holds a Bachelor of Science in Architecture and Urban Planning, as well as a Master of Science from the Integrative Technologies and Architectural Design Research (ITECH) program at the University of Stuttgart. During her studies, she worked for architecture and façade practices in Stuttgart and London and as a research assistant for the University of Stuttgart. Her research at ICD focuses on advanced computational design and construction technologies of novel material systems and their integration in the built environment.

Dr.-Ing. Dylan Wood is a research group leader at the Institute for Computational Design and Construction at the University of Stuttgart. At ICD Dylan leads the Material Programming Research Group and teaches graduate students in related topics. His research is focused on developing intelligent design and fabrication principles for 'smart' shape-changing materials as a form of material robotics that can be applied in building systems, construction, and manufacturing. He has worked extensively in collaboration with material science partners at the ETH, Zurich, EMPA, Dübendorf, and the Physical Intelligence Department at the Max Plank Institute for Physical Systems, Stuttgart. His current doctoral research is funded by the Swiss Commission for Technology and Innovation (CTI / KTI), and the Getty Foundation’s GettyLab. He holds an ITECH, MSc. with distinction from the University of Stuttgart, and a B.Arch, magna cum laude from the University of Southern California. Professionally he has worked as a designer and computational fabrication specialist at Barkow Leibinger Architects in Berlin, Germany and DOSU Studio Architects in Los Angeles, CA.

Curious? Here's a report on the Urbach Tower!

Today’s Timber Plausch interviewers: Christelle El Feghali & Linda Heiß

We use cookies to ensure the proper functioning of our website. For an improved visit experience we use analysis products. These are used when you agree with 'Statistics'. Privacy statement